Understanding Logistics Management: Key Functions and Benefits

Ever wondered how products are made from ordinary materials? OR How do they end up on store shelves in cities far off from where they were manufactured? There is only one answer—logistics management.

Since the outbreak of COVID, the logistics chain management industry has undergone a series of changes. But what is most profound is how this essential piece of operation has become a highly sought after one. For instance, the global logistics market will cross over $445.8 billion by 2027. This impressive figure is proof of the importance of logistics across all shipping points!

This blog will introduce you to a growing aspect of the business world—logistics management and its classification. We'll also discuss the main functions and advantages of logistics chain management.

So, let us unpack what makes logistics the backbone of successful supply chains.

What is Logistics Management?

Logistics management is an essential set of processes involving the movement of raw materials and finished products from their origin to the final consumer. It includes order fulfilment, warehousing, and inventory management—each with their own set of subprocesses like packing, demand prediction, delivery fleet management, etc.

These processes can be manual or automated, depending on the level of digital integration. Artificial intelligence can also predict trends, and then there is machine learning that is used in optimizing operations. Cloud technology and IoT are already trends that are liberating the industry and releasing new growth trajectories.

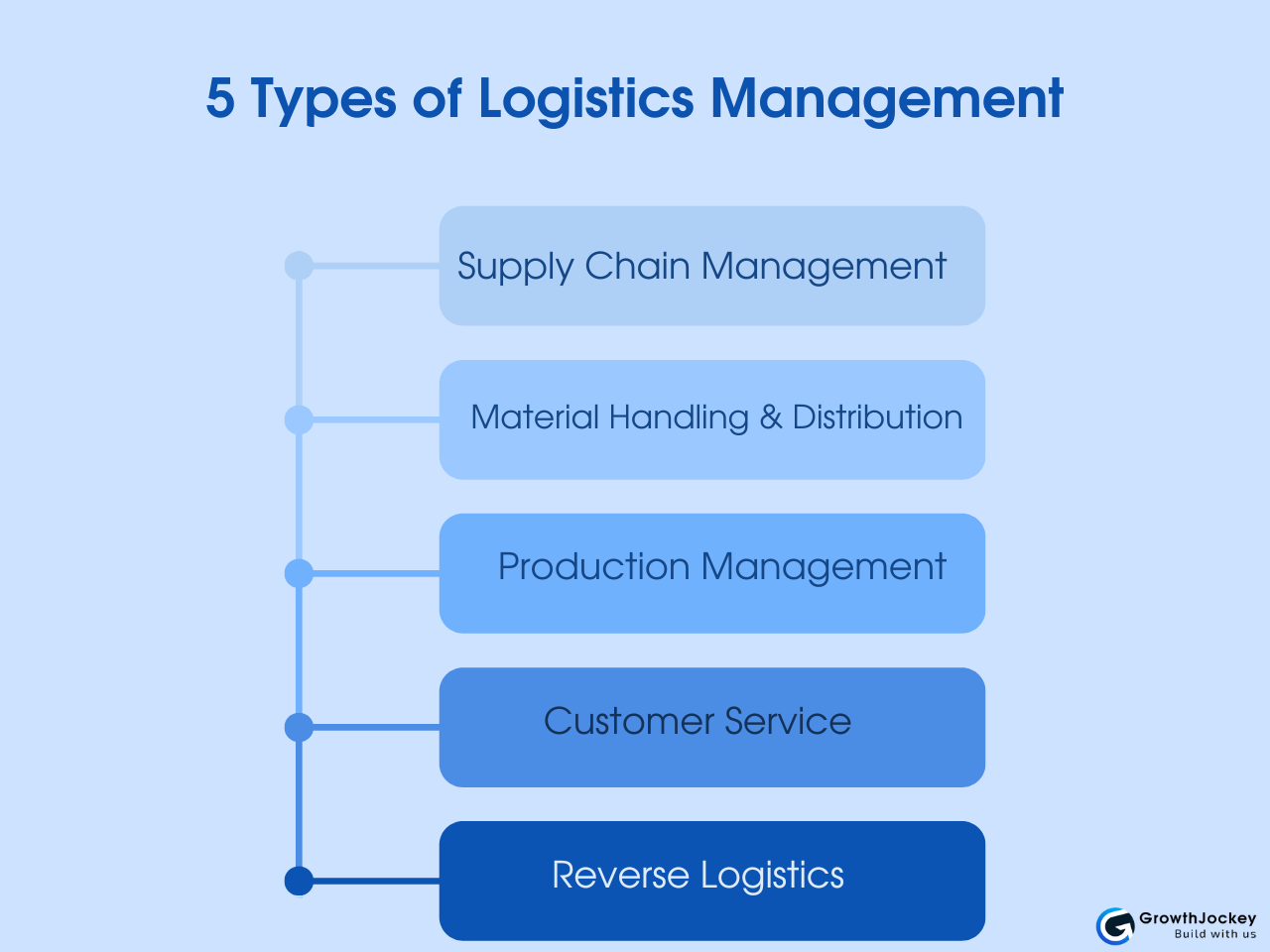

5 Types of Logistics Management

Logistics management is a combination of many tedious and stretched processes, which can be classified into the following types:

1. Supply Chain Management

This type of logistics seeks to arrange, schedule, and acquire the necessary raw materials. In ideal supply chains, the raw materials can always be found at the right locations for production processes.

2. Material Handling and Distribution

It is a process of transferring materials to other areas in a facility or company from a central storeroom or stock point. This ensures prompt distribution of raw materials so that further production or distribution can continue smoothly.

3. Production Management

This relates to the planning, execution, and monitoring of all the stages of production. It coordinates the process, production areas, factories, and warehouses. It is based on product and delivery schedules.

4. Customer Service Management

CSM includes the techniques and technologies used by businesses for analyzing and managing customer interactions. Customer service management refers to the data that these processes generate.

It is an integral type, responsible for several significant stages—from transparent communication to damage-free and timely delivery.

5. Reverse Logistics

This is also referred to as returns management and entails handling order returns.

This is essentially the opposite of other types of logistics, which concern outward movement of materials and goods. Reverse logistics, on the other hand, includes reclamation of supplies from the manufacturer, involving management of returns from the end customer.

Advantages of Logistics Chain Management

An effective logistics chain management strategy allows businesses to meet the needs of consumers faster and at a cheaper cost—all this while acing the competition!

In this piece, we shall look at five primary advantages.

-

Minimized Operating Costs

An effective supply chain network looks at trends and figures. It forecasts future demand and supply requirements. This way, it enhances business efficiency and helps to achieve optimal expenditure in operations.

-

Improved Customer Experience

Logistics strategy goes a long way in enhancing customer experience. This ensures smooth movement of raw materials and finished goods with less interruption and strengthens brand trust.

-

Better Profitability

With smooth logistics, businesses can get a clearer view of their ROI, customers, and operations. Using this information helps companies to meet customer needs and boost profits.

-

Optimized Routing

Well-managed logistics ensure that businesses move raw materials and goods in a coordinated manner.

It ensures on-point route planning, including backup plans. Considering variables like traffic, weather, cargo type, and vehicle fleet improves order fulfillment rates.

-

Intermodal Operations

Improved intermodal operations are safer for the environment and are more reliable. An intermodal operation uses more than one mode to move goods from a manufacturer to a customer. It uses specialized containers to eliminate risks from cargo handling and movement.

A well-crafted logistics strategy can easily lead businesses to getting a hold of these, thereby covering transportation risks!

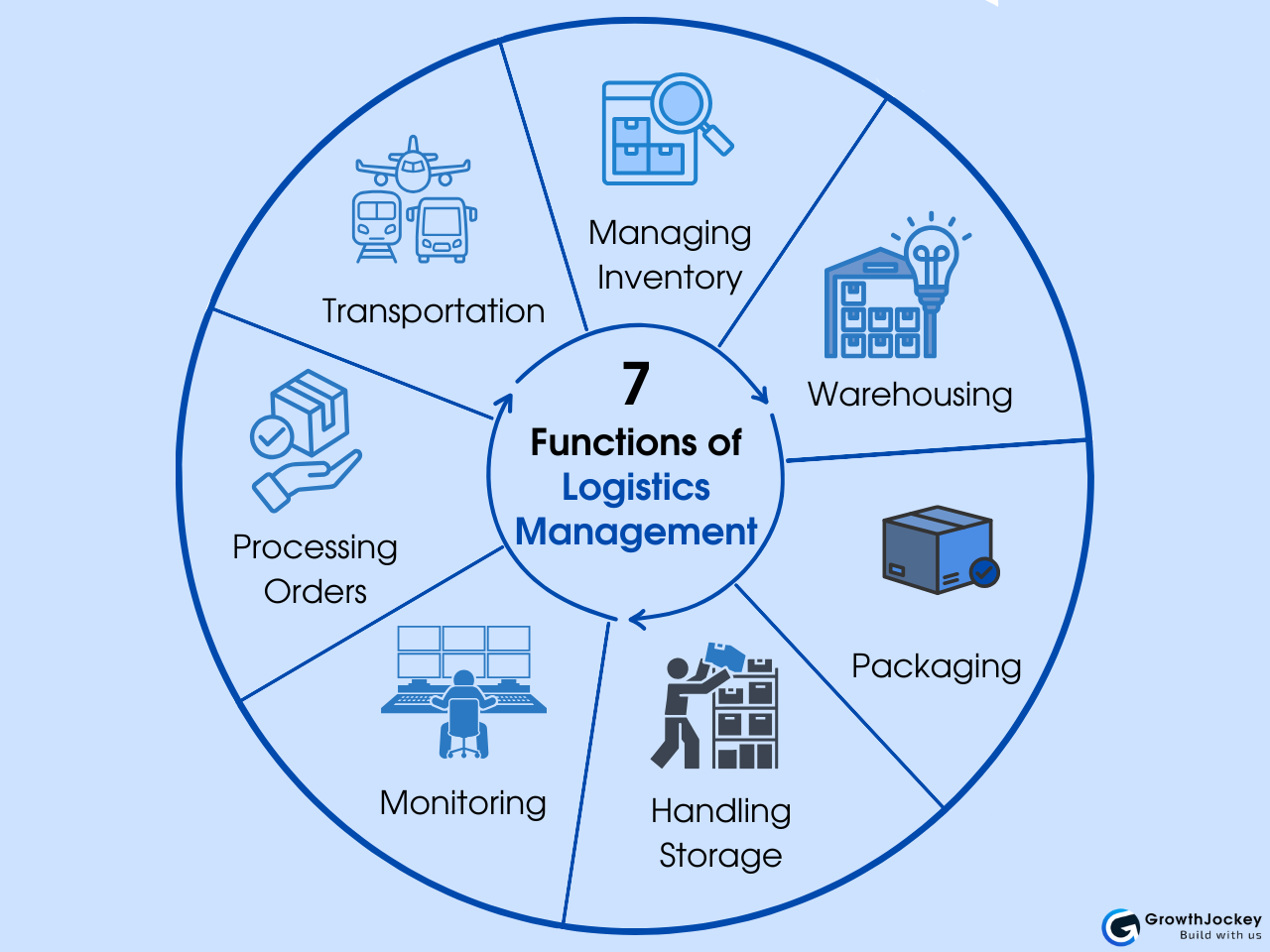

7 Functions of Logistics Management

Having discussed the types and benefits of logistics, it is now important for you to understand that logistics is more than just physical distribution. It involves multiple other functions, such as:

1. Processing Orders

Businesses process orders in many ways, such as by phone calls, email, and websites. A reliable logistics system ensures this processing remains hassle-free and transparent for quick delivery.

2. Transportation

The most visible element of logistics management—good transportation allows items to move from one end to another.

A customer's order is only complete once the product is delivered. At least 60% of logistics costs[1] go into transportation.

3. Managing Inventory

Inventory management is the lifeline of every business.

From the raw materials at hand, to the warehouse and finished products, everything is considered inventory. A good logistics system ensures safety and easy accessibility of these inventories.

4. Warehousing

It includes storage of finished items until delivery to the customer. Warehousing is critical in logistics to cut labour costs and aid inventory control.

5. Packaging

Packaging significantly impacts the effectiveness of the logistics systems. A well-packaged product can be a customer’s delight, promising both safety and easy handling.

If a product is not properly packaged, it may get damaged while in transit. There are also cases where such products occupy too much space on the shelves and warehouses, falling out of care and customers’ choice.

6. Handling Storage

A storage system is critical for optimum warehouse space management. It also ensures quick movement (in both directions) of items from the warehouse.

7. Monitoring

Businesses must constantly monitor transportation, inventory, and warehousing. Each section must always know its supply chain needs, future obligations, and restocking capacity.

Importance of Logistics in Business

Even though we define logistics management as the movement of goods and materials, it does more than that. Here are a few important functions that make logistics the cornerstone of every business.

-

Material Sourcing

Logistics ensures strategic material sourcing by finding not just the cheapest supplier for raw materials, but also factoring in other considerations to cost, such as quality, demand etc. Logistics drives effective sourcing.

-

Transportation

Remember, transportation is the core of logistics, but there is more. Logistics helps find the best transport (land or air). It takes into account factors such as speed, shipment size, and distance, thereby assisting businesses in forming long-lasting partnerships.

-

Order Fulfilment

To complete a transaction, the item must move from the warehouse and get to the customer. Logistics helps move and mark orders as "fulfilled" without major issues, thus smoothening the records.

-

Demand Forecasting

With logistics, there is better and more accurate inventory control through forecasting. Since it constantly takes stock of what is available, logistics ensures that a business never runs out of materials and products.

-

Supply Chain Management

Logistics is critical to the supply chain. It moves materials and goods from suppliers to manufacturers, then to sellers, and lastly to buyers.

A supply chain is basically a series of important transactions. If logistics fail, the supply chain is bound to break down, and transactions risk coming to a halt.

How to Manage Logistics Business with GrowthJockey?

In the realm of logistics, several innovations are shaping businesses. You must partner with efficient supply chain firms; that can be your lifeguards across the sea of strategic logistics transformation!

At GrowthJockey, we see optimized logistics as a mix of traditional supply chain management and new tech. We ensure that AI, blockchain, and IoT combine to improve your operations.

With these technologies, GrowthJockey delivers better visibility, improved demand forecasting, and enhanced traceability for your business. Result? More agile supply chains and flawless logistics management!

Conclusion

Logistics is a complicated process, but at the heart of it is customer service and satisfaction. As a business, better logistics can improve your service.

Proactive planning and data collection can increase your sales and boost earnings and profit. Tech integration and third-party partnerships can help you ace these processes.

Do you need help deciding where to start? Get started with GrowthJockey; it helps businesses improve their logistics.

Frequently Asked Questions

1. How does technology improve logistics management?

From automating processes to real-time tracking, technology transforms supply chains. It streamlines inventory control and boosts communication, revolutionizing logistics efficiency. This digital shift enhances operations, seamlessly connecting every supply chain link.

2. How to employ better logistics management strategies?

Advanced software streamlines operations. Optimized routes slash delivery times. Reduced lead times boost efficiency. Supplier collaboration enhances the supply chain.

These strategies propel businesses toward logistics excellence, maximizing productivity and customer satisfaction.

3. What is the difference between logistics and supply chain management?

Supply chain management oversees the journey of goods. It starts with sourcing supplies and ends with delivering products to customers. It coordinates production, flow, and storage.

Logistics, a crucial component, concentrates on efficient movement and warehousing. Together, they ensure seamless product transitions through every stage of the supply chain.

4. How can effective logistics chain management increase profits?

Effective logistics chain management can directly boost your bottom line by cutting unnecessary costs. Optimizing transportation routes, for example, uses less fuel and time. Streamlining your inventory prevents overstocking or running out of products. Both can cost you.

Also, faster, more accurate deliveries avoid costs from returns and late fees. All these improvements add up, allowing you to keep more revenue and boost your profits.

5. How to tell if my current logistics management needs improvement?

Simple- Do you experience late deliveries, high shipping costs, or inventory shortages? Your logistics need a tune-up!